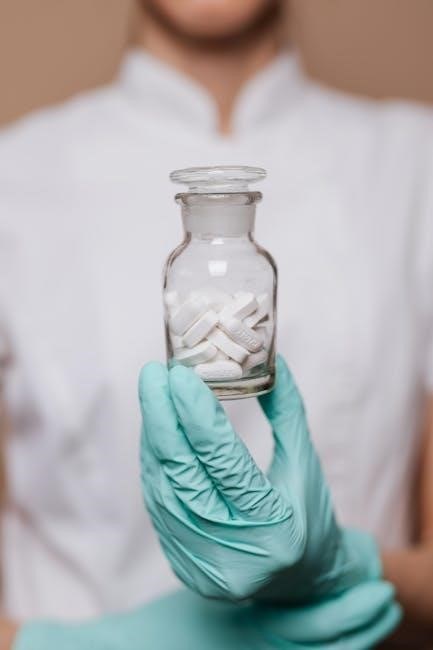

Overview of Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition by Linda E. McCuistion et al., published by Saunders, is a comprehensive guide for nursing students. It focuses on patient-centered care, integrating pharmacology into nursing practice, and prepares students for the NCLEX exam with streamlined content and additional review questions.

The 10th edition of Pharmacology: A Patient-Centered Nursing Process Approach introduces a refined framework for understanding pharmacology in nursing practice. It emphasizes patient-centered care, integrating pharmacological concepts with the nursing process to enhance clinical decision-making. This edition features a streamlined prototype approach, making complex drug information more accessible; With a focus on NCLEX preparation, it includes additional review questions to address the expanding pharmacology content on the exam. The text also highlights drug development, ethical considerations, and pharmacokinetics, providing a comprehensive foundation for nursing students and professionals alike.

1.2 Authors and Publication Details

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition is authored by Linda E. McCuistion, PhD, MSN, RN; Jennifer J. Yeager, RN, MSN; Mary Beth Winton, PhD; and Kathleen DiMaggio, RN, MSN. The book is published by Saunders, a renowned medical and nursing education publisher. The authors bring extensive expertise in nursing education and pharmacology, ensuring the content is both accurate and accessible. Their collaborative effort provides a comprehensive resource tailored for nursing students and professionals, focusing on patient-centered care and clinical application. The publication is part of a long-standing series trusted for its evidence-based approach and practical insights.

1.3 ISBNs for Digital and Print Versions

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition is available in both digital and print formats. For the digital version, the ISBNs are 9780323654326 and 0323654320, while the print version carries ISBNs 9780323642477 and 0323642470. These identifiers ensure easy access to the book through various online platforms and bookstores. The digital formats are DRM-free, allowing readers to access the content on multiple devices without restrictions. This flexibility makes it convenient for students and professionals to study pharmacology efficiently, whether they prefer e-books or traditional printed materials.

Key Features of the 10th Edition

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition features a patient-centered nursing process, streamlined prototype approach, and emphasis on nursing care. Additional review questions enhance NCLEX preparation.

2.1 Patient-Centered Nursing Process Approach

The 10th Edition emphasizes a patient-centered nursing process approach, focusing on individualized care and evidence-based practices. This method integrates assessment, diagnosis, planning, implementation, and evaluation to ensure personalized treatment. By prioritizing patient needs, nurses can deliver targeted interventions, enhancing therapeutic outcomes. The approach also encourages critical thinking and clinical decision-making, aligning pharmacological therapies with patient-specific goals. This structured framework ensures that pharmacology is applied effectively and compassionately, making it a cornerstone of modern nursing practice.

2.2 Streamlined Prototype Approach

The 10th Edition incorporates a streamlined prototype approach to simplify pharmacology learning. This method organizes drugs by prototype, focusing on key classifications and mechanisms. By emphasizing commonalities and differences, it reduces complexity and enhances understanding. The approach aids in identifying drug families, their effects, and interactions, making it easier for students to apply pharmacological concepts in clinical settings. This structured yet concise framework ensures that learners grasp essential drug therapies without unnecessary details, aligning with the book’s patient-centered focus and promoting practical application in nursing care.

2.3 Emphasis on Nursing Care

The 10th Edition places a strong emphasis on nursing care, ensuring that pharmacology is integrated into patient-centered practice. It provides practical tools and guidelines for nurses to administer medications safely and effectively. The text highlights the nurse’s role in monitoring drug effects, educating patients, and managing side effects. By focusing on care planning and evidence-based practices, the book bridges pharmacological theory with real-world application. This approach equips nurses with the knowledge to deliver personalized, effective care, aligning with the broader goals of patient safety and optimal health outcomes in clinical settings.

2.4 Additional Student Review Questions

The 10th Edition includes additional student review questions to enhance learning and preparation for the NCLEX exam. These questions cover pharmacology concepts, dosage calculations, and patient care scenarios, ensuring a comprehensive understanding. They are designed to reinforce key content and help students apply theoretical knowledge in clinical settings. With a focus on critical thinking, the questions simulate real-world challenges, making them an invaluable tool for exam success and professional competence. This feature underscores the book’s commitment to supporting nursing students in mastering pharmacology effectively.

Digital and Print Formats

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition is available in both digital and print formats. The digital version includes DRM-free EPUB and PDF options, accessible on various devices, while the print edition offers a traditional learning experience. This flexibility ensures students can choose the format that best suits their needs, with digital versions often offering cost savings compared to print.

3.1 Availability of eBooks and PDFs

The 10th Edition of Pharmacology: A Patient-Centered Nursing Process Approach is readily available in eBook and PDF formats, ensuring accessibility for students. These digital versions are DRM-free, allowing readers to access content on multiple devices, including PCs, Android, and iOS platforms. The eBook can be downloaded for offline reading, highlighting, and note-taking, enhancing study flexibility. PDF formats provide clear layouts, ideal for revision and reference. This digital accessibility makes it easier for nursing students to study pharmacology efficiently, aligning with their learning preferences and schedules.

3.2 DRM-Free EPUB and PDF Formats

The 10th Edition is available in DRM-free EPUB and PDF formats, ensuring unrestricted access across various devices. These formats allow users to read, highlight, and annotate content without restrictions, enhancing flexibility for nursing students. The DRM-free feature enables offline access, making it ideal for studying on-the-go. Both EPUB and PDF versions are compatible with PCs, tablets, and smartphones, providing a seamless reading experience. This accessibility ensures that students can efficiently prepare for exams like the NCLEX while benefiting from a well-structured, patient-centered approach to pharmacology education.

3.4 Cost Savings for Digital Editions

Digital editions of Pharmacology: A Patient-Centered Nursing Process Approach offer significant cost savings compared to print versions. Students can save up to 80% by opting for eTextbooks or PDFs, making high-quality educational resources more accessible. The digital format also eliminates shipping costs and reduces environmental impact, appealing to budget-conscious learners. With DRM-free access, users can easily download and store content, ensuring long-term availability without additional fees. This affordability makes the 10th Edition an attractive choice for nursing students seeking comprehensive pharmacology education at a fraction of the cost of traditional textbooks.

NCLEX Preparation and Professional Nursing

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition aids NCLEX success with focused pharmacology content and nursing care guidance, ensuring professional nursing excellence and patient safety.

4.1 Pharmacology Coverage on NCLEX Exam

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition extensively covers pharmacology content relevant to the NCLEX exam. The textbook emphasizes patient safety, drug classifications, dosages, and side effects, aligning with NCLEX test plans. It includes additional student review questions to help nursing candidates master pharmacology concepts. The streamlined prototype approach ensures clarity and focus, making complex drug information accessible. This edition prepares aspiring nurses for the growing pharmacology emphasis on the NCLEX, ensuring they are well-equipped for both the exam and real-world nursing practice.

4.2 Nursing Guidance for Professional Success

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition provides comprehensive guidance for nursing professionals. It emphasizes patient-centered care, ethical considerations, and evidence-based practices. The textbook supports nurses in developing critical thinking skills for drug administration, monitoring, and patient education. With a focus on real-world application, it helps nurses integrate pharmacology into their practice seamlessly. The structured approach ensures professionals are well-prepared to address diverse patient needs, fostering both clinical competence and compassionate care. This edition is a valuable resource for advancing nursing expertise and lifelong professional development.

Core Content and Structure

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition offers a structured framework, integrating pharmacology into patient care. Chapters cover drug development, pharmacokinetics, pharmacodynamics, and ethical considerations, ensuring a comprehensive understanding of pharmacology in nursing practice.

5.1 Nursing Process and Patient-Centered Care

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition emphasizes a structured framework for patient-centered care. The nursing process—assessment, diagnosis, planning, implementation, and evaluation—is seamlessly integrated with pharmacology. This approach ensures nurses deliver personalized, evidence-based care. The text connects pharmacological interventions to patient outcomes, fostering a deep understanding of how medications affect individuals. By prioritizing patient-centered care, the book equips nurses with the tools to make informed decisions, enhancing therapeutic responses and improving patient safety.

5.2 Drug Development and Ethical Considerations

The 10th Edition delves into the intricate process of drug development, from discovery to FDA approval, highlighting the role of nurses in patient-centered care. It explores ethical considerations, including patient safety, informed consent, and cultural sensitivity. The text emphasizes the importance of evidence-based practices and the nurse’s responsibility to advocate for patients throughout the medication lifecycle. By addressing these critical issues, the book prepares nurses to navigate the complexities of pharmacology with integrity and compassion, ensuring ethical standards are upheld in clinical settings.

5.3 Pharmacokinetics and Pharmacodynamics

Pharmacokinetics and pharmacodynamics are foundational concepts in pharmacology, focusing on drug movement through the body and their effects on biological systems. The 10th Edition explains how absorption, distribution, metabolism, and excretion influence drug efficacy and safety. It also explores pharmacodynamics, detailing how drugs interact with receptors to produce therapeutic and adverse effects. Nurses learn to apply these principles to optimize dosing regimens, monitor for side effects, and tailor treatments to individual patient needs, ensuring safe and effective medication therapy. This section emphasizes the nurse’s role in managing pharmacokinetic and pharmacodynamic variability for personalized patient care.

Study Resources and Supplements

Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition includes a comprehensive study guide with review questions and case studies. A accompanying test bank provides NCLEX-style questions, reinforcing pharmacology concepts and clinical applications for nursing students. These resources enhance learning and exam preparation, ensuring a deeper understanding of pharmacology principles and their practical use in patient care.

6.1 Study Guide for Pharmacology

The study guide accompanying Pharmacology: A Patient-Centered Nursing Process Approach, 10th Edition offers comprehensive review questions and case studies. It reinforces key pharmacology concepts, dosage calculations, and patient-centered care. Designed to complement the textbook, the guide helps students apply theoretical knowledge to clinical scenarios, enhancing their critical thinking and problem-solving skills. Additional practice exercises focus on NCLEX-style questions, ensuring exam readiness. The guide is structured to align with the textbook chapters, providing a seamless learning experience and reinforcing the integration of pharmacology into nursing practice for optimal patient outcomes.

6.2 Test Bank for the 10th Edition

The Test Bank for the 10th Edition of Pharmacology: A Patient-Centered Nursing Process Approach is a valuable resource for instructors and students. It contains a wide range of NCLEX-style questions, case studies, and practice exercises tailored to the textbook content. The test bank helps students assess their understanding of pharmacology concepts, dosage calculations, and patient-centered care. Instructors can use it to create quizzes and exams, ensuring comprehensive coverage of key topics. The questions are designed to promote critical thinking and application of knowledge, aligning with the textbook’s focus on practical nursing skills and patient outcomes.

The Nursing Process in Pharmacology

The nursing process provides a structured framework for patient-centered care, integrating pharmacology into a cohesive approach. Key steps include: Assessment, Diagnosis, Planning, Implementation, and Evaluation.

7.1 Assessment, Diagnosis, Planning, Implementation, and Evaluation

The nursing process in pharmacology involves a systematic approach to patient care. Assessment gathers patient data, including medical history and current medications. Diagnosis identifies actual or potential health issues. Planning establishes goals and outcomes for patient care. Implementation executes the care plan, focusing on safe medication administration. Evaluation assesses the effectiveness of interventions and patient progress. This structured framework ensures personalized, evidence-based care, aligning pharmacological interventions with patient needs and promoting optimal health outcomes. It also supports nurses in understanding pharmacology’s role in achieving desired therapeutic effects while minimizing adverse reactions.

7.2 Integration of Pharmacology into Nursing Practice

Pharmacology is seamlessly integrated into nursing practice through a structured framework that emphasizes patient-centered care. The nursing process provides a clear pathway for applying pharmacological principles, ensuring safe and effective medication administration. Nurses use assessment data to identify patient needs, diagnose potential issues, and develop individualized care plans. Implementation involves administering medications and educating patients, while evaluation monitors outcomes and adjusts interventions. This holistic approach ensures pharmacology is applied practically, promoting therapeutic effects and minimizing adverse reactions. The 10th edition reinforces this integration, making it easier for nurses to connect pharmacological knowledge with real-world patient care scenarios.