Manual card imprint is a traditional payment method using physical machines to capture card details for transactions, ideal for offline processing but requiring manual labor and oversight․

1․1 What is Manual Card Imprint?

Manual card imprint is a traditional payment method where a physical machine captures card details by pressing the card into an inked pad, creating a visible imprint․ This process, often used in offline transactions, requires a manual imprinter tool․ It’s commonly used by small businesses for its simplicity but has largely been replaced by digital payment methods due to security concerns and efficiency․

1․2 Historical Context and Evolution

Manual card imprint originated in the 1950s as credit cards gained popularity․ Early devices used carbon paper to create imprints, evolving over decades to include more sophisticated tools․ The rise of electronic payment systems in the 1980s gradually reduced their use, but manual imprinters remain relevant for offline transactions in niche settings, such as remote locations or events without internet access, preserving their utility in specific scenarios․

How Manual Card Imprint Works

Manual card imprint involves using a physical imprinter to transfer card details onto paper, creating a carbon copy for transactions without electronic processing, requiring manual effort and verification․

2․1 The Process of Creating a Manual Card Imprint

Creating a manual card imprint involves placing the card in an imprinter, adding a paper slip, and pressing down to transfer the card details, including the number and expiration date, onto the paper․ This process is typically used for offline transactions and requires careful handling to ensure accurate data capture and security․

2․2 Tools and Equipment Required

The primary tools needed for manual card imprinting include a manual card imprinter, paper slips, and ink ribbons․ The imprinter is a small, handheld device that presses the card details onto the paper․ Additional supplies like pens for customer signatures and storage for completed slips are also essential for completing transactions efficiently and securely․

Advantages of Manual Card Imprint

Manual card imprint offers reliability for offline transactions, simplicity in operation, and cost-effectiveness, making it a practical solution for small businesses and remote locations․

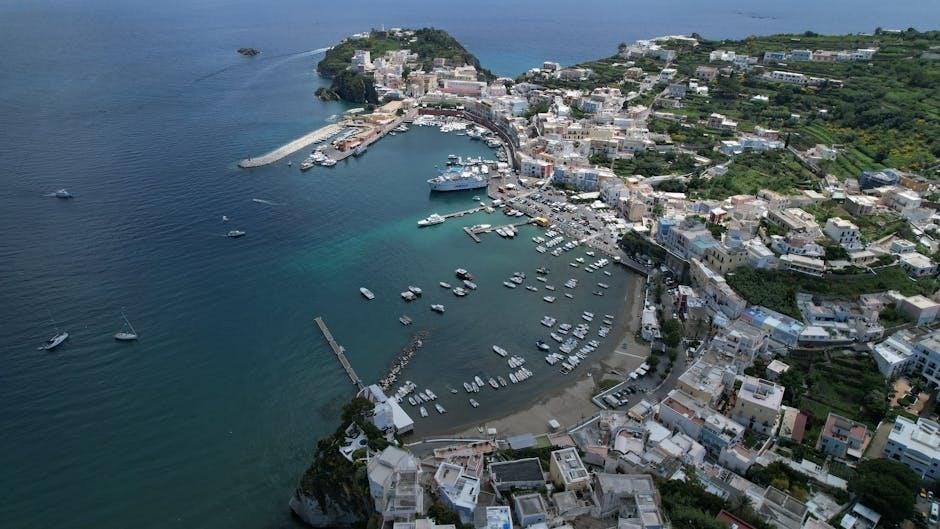

3․1 Offline Payment Processing

Manual card imprint enables businesses to process transactions without internet connectivity, making it ideal for remote locations or areas with unreliable online access․ This method ensures continuity in sales by capturing card details physically, which can be processed later․ It is particularly useful for merchants in rural areas, events, or temporary setups where online systems are not feasible, ensuring uninterrupted revenue generation and customer satisfaction․

3․2 Simplicity and Cost-Effectiveness

Manual card imprint is a straightforward method requiring minimal training and basic tools, making it accessible for small businesses․ It eliminates the need for expensive technology or subscription services, reducing overhead costs․ This simplicity ensures that businesses can operate efficiently without significant financial investment, making it a budget-friendly option for merchants seeking to keep operations uncomplicated and affordable․

Disadvantages of Manual Card Imprint

Manual card imprint lacks advanced security features, making it vulnerable to fraud․ The process is time-consuming and requires physical handling, increasing the risk of human error and theft․

4․1 Security Risks

Manual card imprint systems pose significant security risks due to the lack of encryption and digital tracking․ Sensitive card data is vulnerable to theft, misuse, or unauthorized access․ Without advanced fraud detection, businesses and customers are exposed to potential scams and data breaches, highlighting the need for stricter oversight and modern security measures to safeguard financial information effectively․

4․2 Manual Labor and Time-Consuming Process

Manual card imprint requires physical handling of payment slips and imprinters, making it labor-intensive and time-consuming․ Each transaction demands staff attention, slowing down operations, especially in high-volume environments․ This outdated method lacks automation, increasing the potential for human error and reducing efficiency compared to modern, streamlined payment solutions that prioritize speed and accuracy․

Security Measures for Manual Card Imprint

Manual card imprint requires strict handling of sensitive data to prevent fraud․ Secure storage of imprint slips and limited access to customer information are critical for safeguarding transactions effectively․

5․1 Protecting Customer Data

Manual card imprint systems require stringent measures to protect customer data․ Sensitive information, such as card numbers and expiration dates, must be stored securely to prevent unauthorized access․ Implementing strict access controls, encrypting data, and training staff on data handling are essential to mitigate fraud risks․ Regular audits and compliance with payment industry standards further enhance security, ensuring customer trust and safeguarding transactions․

5․2 Compliance with Payment Regulations

Manual card imprint systems must adhere to payment industry regulations, such as PCI DSS, to ensure secure transactions․ Businesses using these systems are required to maintain proper documentation, train staff on handling sensitive data, and conduct regular audits․ Compliance helps prevent fraud and protects both businesses and customers from potential legal and financial repercussions associated with data breaches․

Modern Alternatives to Manual Card Imprint

Modern alternatives include digital payment methods like contactless cards and mobile payments, offering enhanced security, efficiency, and convenience compared to traditional manual systems․

6․1 Digital Payment Methods

Digital payment methods like contactless cards, mobile wallets, and online transactions offer faster and more secure alternatives to manual card imprints․ These technologies reduce the need for physical equipment, enhancing efficiency and customer experience while minimizing fraud risks through encryption and tokenization, making them preferred choices for modern businesses and consumers alike․

6․2 EMV Chip Technology

EMV chip technology offers enhanced security and efficiency compared to manual card imprints․ It uses encrypted data and tokenization to prevent fraud, reducing reliance on physical impressions․ Widely adopted globally, EMV chips ensure secure, contactless, and faster transactions, making them a reliable alternative for businesses transitioning from outdated manual systems to modern, secure payment processing solutions․

Legal and Regulatory Considerations

Manual card imprint requires strict adherence to legal and regulatory standards to ensure secure transactions and protect customer data, with businesses liable for fraud and non-compliance issues․

7․1 PCI DSS Compliance

Manual card imprint systems must comply with PCI DSS standards to ensure secure handling of cardholder data․ This includes protecting sensitive information, implementing access controls, and regularly auditing processes to maintain compliance and avoid penalties․

7․2 Liability and Fraud Prevention

Manual card imprint systems pose higher risks of fraud and data breaches․ Merchants must implement robust fraud prevention measures, such as verifying signatures and securing imprinted data, to minimize liability and protect customer information from unauthorized access․

Case Studies and Real-World Applications

This section explores real-world applications of manual card imprint, highlighting industries still using the method and the challenges they face in a digital payment landscape․

8․1 Industries Still Using Manual Card Imprint

Certain industries, such as small businesses, rural shops, and hospitality services, continue to use manual card imprint due to its simplicity and reliability in offline environments․ Despite advancements in digital payments, some businesses prefer the cost-effectiveness and ease of manual imprinters, especially in areas with limited internet access․ However, this method remains vulnerable to security risks and requires meticulous record-keeping to prevent fraud․

8․2 Success Stories and Challenges

While manual card imprint remains niche, some small businesses and rural shops report success due to its simplicity in offline transactions․ However, challenges like security risks, manual labor, and time-consuming processes persist․ Compliance with payment regulations is essential to mitigate fraud risks․ Despite these drawbacks, certain industries continue to rely on this method, highlighting its enduring relevance in specific scenarios․

The Future of Manual Card Imprint

Manual card imprint faces decline as technology advances, shifting towards digital payment solutions and EMV chip technology, though niche industries may retain them for specific operational needs․

9․1 Technological Advancements

Technological advancements, such as digital payment systems and EMV chip technology, are rapidly replacing manual card imprint methods․ These innovations offer faster, more secure, and efficient payment processing, reducing the need for physical imprinting․ As contactless payments and mobile wallets gain popularity, manual systems are becoming obsolete, pushing businesses toward modern, high-tech solutions to meet consumer demands and enhance transaction security․

9․2 Phasing Out of Manual Systems

Manual card imprint systems are gradually being phased out due to their inefficiencies and security risks․ The rise of digital payment methods and EMV technology has accelerated this decline․ Businesses are shifting to modern solutions to enhance security and streamline transactions․ While some industries still use manual systems, their continued use is becoming increasingly impractical, prompting a widespread transition to more advanced payment processing methods․