Honeywell light switch timers offer convenient control over lighting schedules, enhancing energy efficiency and home automation․ These programmable devices are easy to install and operate, providing flexible solutions for managing light usage while reducing energy waste through advanced features and smart automation capabilities․

1․1 Overview of Honeywell Light Switch Timers

Honeywell light switch timers are designed to provide precise control over lighting systems, offering flexibility for homeowners to manage their lighting schedules․ These devices are compatible with various lighting types, including LED and halogen, and feature programmable settings for automatic operation․ With options for 7-day programming and manual override, they ensure convenience while optimizing energy usage and reducing waste․

1․2 Benefits of Using Programmable Timers

Programmable timers enhance energy efficiency by automating lighting schedules, reducing manual oversight․ They offer customizable settings, allowing users to tailor lighting operations to their needs․ These timers also provide manual override for flexibility and convenience․ By automating light usage, they help reduce energy waste and lower utility bills, making them a practical and cost-effective solution for modern homes․

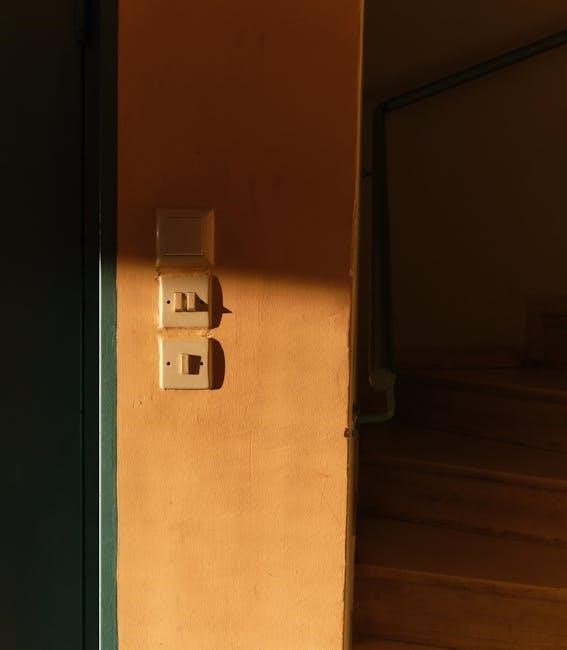

Safety Precautions

Always cut power at the circuit breaker before installation to avoid electric shock․ Ensure proper wiring connections and follow manufacturer guidelines to prevent hazards during setup․

2․1 Essential Safety Measures Before Installation

Always cut power at the circuit breaker before starting installation to avoid electric shock․ Ensure the power is off using a voltage tester before handling any wires․ This prevents accidental electrical discharge or shocks․ When removing the existing switch, take note of the wire connections to avoid mistakes during the new installation․ Additionally, ensure all wires are properly connected․

Installation Steps

Begin by cutting power at the circuit breaker․ Remove the old switch, then install the new Honeywell timer switch, ensuring correct wire connections, including neutral, line, and load wires․

3․1 Preparing for Installation

Before installing, ensure the power is off at the circuit breaker and verify using a voltage tester․ Gather tools like a screwdriver and wire strippers․ Check compatibility with your lighting load and wiring setup․ Read the manual for model-specific instructions․ Set the time and date before starting the installation process to ensure smooth operation post-installation․

3․2 Removing the Old Switch

Turn off power at the circuit breaker and verify with a voltage tester․ Remove the faceplate and screws to access the old switch․ Gently pull it forward and disconnect wires one by one, noting their connections for later reference․ For 3-way setups, identify and label the common wire to ensure proper reinstallation of the new timer switch․

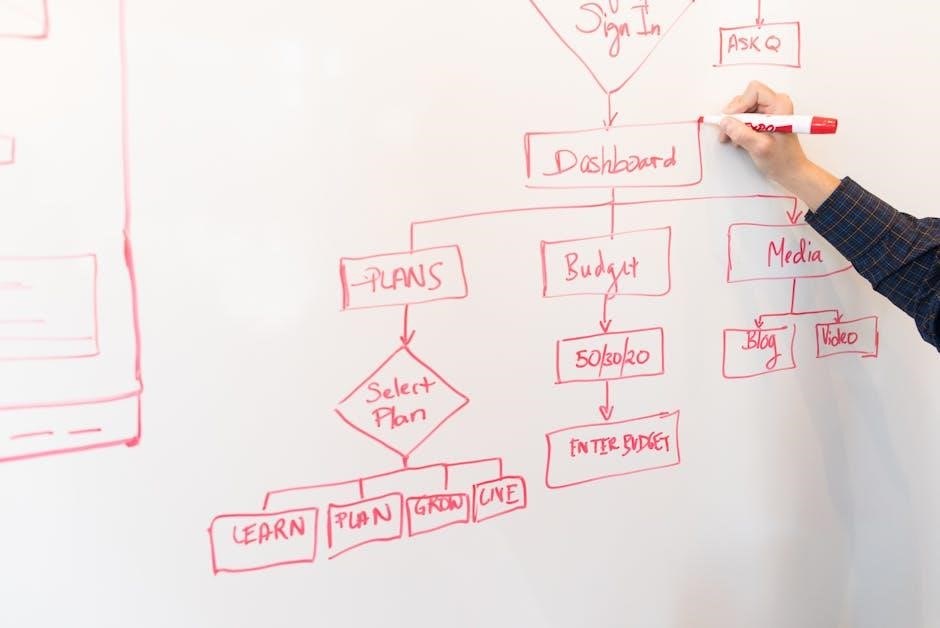

3․3 Installing the New Honeywell Timer Switch

Mount the Honeywell timer switch in the electrical box, ensuring it is secure․ Connect the wires according to the manual, matching line, load, and neutral wires․ Refer to the installation diagram for clarity․ Tighten all connections firmly․ Restore power at the circuit breaker and test the switch to ensure proper function․ Set the time and date before programming schedules․

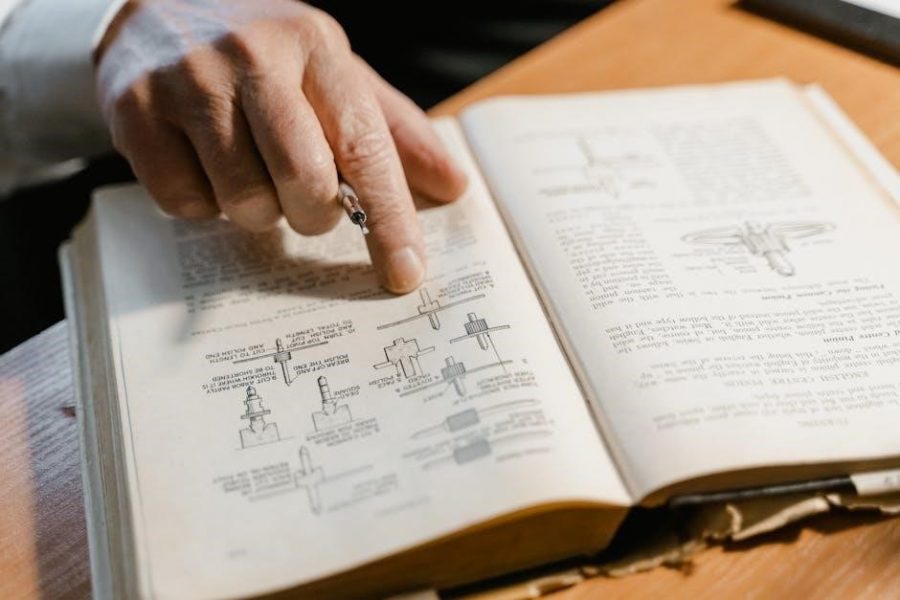

3․4 Connecting Wires Correctly

Connect the load wire (black) to the “LOAD” terminal and the neutral wire (white) to the “NEUTRAL” terminal․ Attach the line wire (black) to the “LINE” terminal․ Ensure all connections are tight and secure․ Refer to the installation diagram for guidance․ Double-check connections before restoring power to avoid electrical issues․

Programming the Timer

Set the time and date first for accurate scheduling․ Use manual override to control lights instantly or create custom schedules for automated operation, ensuring seamless lighting management․

4․1 Setting the Time and Date

Start by setting the correct time and date on your Honeywell timer switch․ Press and hold the Day button to access the time-setting mode․ Use the Hour and Min buttons to adjust the time․ Ensure the switch is in AUTO mode for scheduled operations․ Proper time and date settings are crucial for accurate automation of your lighting schedule․

4․2 Creating a Schedule

Press and hold the main button to enter programming mode․ Use the navigation buttons to set your desired on/off times for each day․ Program up to 7 different schedules for tailored lighting control․ Save your settings to ensure the timer follows your preferred schedule․ This feature allows you to customize lighting automation, optimizing convenience and energy efficiency throughout the week․

4․3 Using Manual Override

For temporary control, press the main button briefly to toggle the light on or off․ The Manual Override mode allows you to bypass the programmed schedule․ The icon appears when the switch is in manual mode․ This feature is ideal for occasional adjustments without altering your preset timings, ensuring flexibility while maintaining your automated lighting routines when desired․

Advanced Features

Honeywell timers offer energy-saving modes and customizable settings, allowing users to tailor lighting schedules to their preferences․ These features enhance efficiency and provide flexible automation for various lighting needs․

5․1 Energy-Saving Modes

Honeywell timers feature energy-saving modes that automatically adjust lighting schedules based on sunrise and sunset times․ These modes reduce energy consumption by optimizing light usage, ensuring lights are only on when needed․ Customizable settings allow users to create efficient schedules, while manual override provides flexibility․ Compatibility with LED and CFL bulbs further enhances energy efficiency, helping to lower utility bills and extend bulb life․

5․2 Customizing Timer Settings

Honeywell timers allow users to customize settings for personalized control, offering flexibility in scheduling․ Adjust timers to fit specific needs, such as different on/off times for weekdays and weekends․ Easily modify settings to optimize energy usage and comfort․ Customizable options ensure lighting aligns with daily routines, enhancing convenience and efficiency while tailoring to individual preferences and lifestyles․

Troubleshooting Common Issues

Troubleshoot issues like display not turning on, incorrect time, or lights not responding․ Check power connections, ensure proper wiring, and verify time settings for accurate operation․

6․1 Diagnosing and Fixing Common Problems

Identify issues like timers not turning on or incorrect lighting schedules․ Check power connections, ensure neutral wires are properly linked, and verify time settings․ If the display is blank, reset the timer by cycling the circuit breaker․ For unresponsive lights, confirm wiring accuracy and test manual override functionality to resolve operational glitches effectively․

Model-Specific Instructions

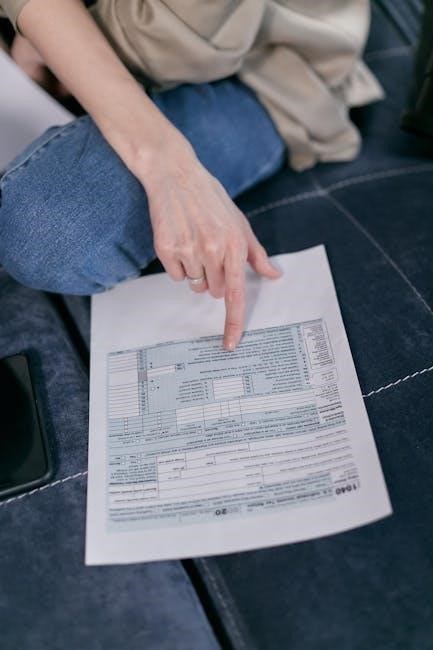

Various Honeywell models like RPLS730B1000, RPLS740B/RPLS741B, and RPLS541A1001 require specific installation and programming steps․ Each model offers unique features and wiring requirements, ensuring optimal performance when instructions are followed precisely․

7․1 Honeywell RPLS730B1000 Instructions

The Honeywell RPLS730B1000 is a 7-Day Solar Programmable Wall Switch designed for single-pole installations․ To install, cut power at the circuit breaker, then connect the load, neutral, and line wires․ Set the time and date before first use․ This model features automatic timer settings based on sunset and offers manual override for flexible control․ It is compatible with incandescent, halogen, and LED lights, ensuring energy efficiency and convenience․

7․2 Honeywell RPLS740B/RPLS741B Instructions

The Honeywell RPLS740B/RPLS741B 7-Day Solar Programmable Wall Switch supports single-pole and 3-way installations․ For installation, cut power, remove the old switch, and connect the load, neutral, and line wires as per the diagram․ The switch automatically turns lights on at sunset and off at 11 PM by default․ Manual override is available for quick adjustments, and it works with LED, halogen, and incandescent lights for energy-efficient control․

7․3 Honeywell RPLS541A1001 Instructions

The Honeywell RPLS541A1001 is a 7-Day Solar Programmable Wall Switch designed for single-pole and 3-way installations․ It requires a neutral wire and is compatible with LED, halogen, and incandescent lights․ After cutting power, remove the old switch and connect wires according to the diagram; The switch automatically turns lights on at sunset and off at 11 PM, with manual override available for quick adjustments, ensuring energy-efficient control and ease of use․

3-Way Installation

A 3-way installation involves multiple switches controlling one light․ Honeywell timers are compatible with such setups, requiring identification of the common wire for proper connections․

8․1 Understanding 3-Way Switch Setups

A 3-way switch setup allows control of a single light from multiple locations․ It involves three wires: two traveler wires and one common wire․ Identifying the common wire is crucial for correct installation; Honeywell timers are compatible with 3-way setups, providing flexible control over lighting․ Proper wiring ensures smooth operation and energy efficiency, making it ideal for managing lights in larger spaces effectively and conveniently․

8․2 Special Considerations for 3-Way Installations

For 3-way setups, identify and label the common wire to ensure proper functionality․ Verify load requirements, as timers may not work with loads below 40W or above 500W․ Ensure the neutral wire is connected to avoid power issues․ Test all switches post-installation to confirm synchronization․ Proper wiring is critical to prevent malfunctions and ensure smooth operation of the timer switch in a 3-way configuration․

Maintenance and Care

Regularly check wire connections and ensure the timer is clean․ Update firmware if available․ Replace batteries if applicable․ Avoid exposing the switch to moisture or extreme temperatures․

9․1 Regular Maintenance Checks

Perform regular checks to ensure optimal performance․ Verify wire connections are secure and clean․ Update firmware if available to maintain functionality․ Clean the timer face and buttons to prevent dust buildup․ Avoid exposing the switch to moisture or extreme temperatures․ Ensure compatibility with your lighting load to prevent malfunctions․ Schedule periodic inspections to maintain reliability and efficiency․

9․2 Replacing Parts

Replace worn or faulty components promptly to maintain functionality․ Disconnect power before starting any replacement․ Use genuine Honeywell parts for compatibility and safety․ Remove the old part carefully, ensuring wires remain intact․ Install the new component as per instructions, securing connections firmly․ Reconnect power and test the timer to ensure proper operation․ Regular part replacement prevents potential malfunctions and extends the timer’s lifespan․

Energy Efficiency and Savings

Honeywell timers optimize energy use by automating lighting schedules, reducing waste, and lowering bills through precise control and smart automation features․

10․1 How Timers Reduce Energy Consumption

Honeywell timers reduce energy consumption by automating lighting schedules, ensuring lights are only on when needed․ They prevent unnecessary usage through programmed on/off times, manual overrides, and compatibility with energy-efficient lighting like LEDs․ These features collectively minimize wasted energy, lower utility bills, and promote sustainable practices․

10․2 Maximizing Energy Savings

Honeywell timers maximize energy savings by allowing precise programming of on/off times, reducing unnecessary usage․ Manual override and adaptive scheduling ensure lights operate only when needed․ Compatibility with LED and energy-efficient lighting further enhances savings․ Regular schedule updates and optimized settings help lower utility bills while promoting eco-friendly practices․

Honeywell light switch timers enhance energy efficiency and convenience through programmable features․ For further assistance, visit Honeywell’s official website or consult the comprehensive user manual provided with your model․

11․1 Summary of Benefits

Honeywell light switch timers provide enhanced energy efficiency, convenient scheduling, and seamless automation․ They reduce energy waste by automating lighting control, offer manual override for flexibility, and are compatible with various lighting types․ These timers are user-friendly, with features like sunset and sunrise settings, ensuring optimal light usage while minimizing electricity consumption․ They are an ideal solution for modern, eco-conscious homes․

11․2 Where to Find Further Assistance

For additional support, visit Honeywell’s official website for detailed manuals, troubleshooting guides, and FAQs․ Customer service is available via phone or email for personalized assistance․ Online forums and YouTube tutorials also offer step-by-step guidance․ Refer to specific model manuals like RPLS530A or RPLS540A for tailored instructions․ Local hardware stores may provide hands-on assistance for complex installations or repairs․